To get to be a farmer, Brian Martin first has to be a decider. What to grow. How much of it to grow? What seed to use? Where to grow it. When to plant it — both in time of day, and in time of season. How far apart (and deep) to plant it? When to treat it. How to treat it. When to harvest it.

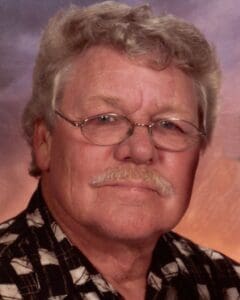

For the third-generation Kansas farmer and his wife Lori, some of these decisions — like the one they made to convert to no-till operations in the 1990s — are easier if only in that they’re made once and at a bigger scale. Others are made every day and for every acre of land.

Despite his informed intuition and expertise through experience over decades of farming, making these decisions at the level of precision required by modern agriculture can be difficult.

Any number of factors — all of which independently vary across hundreds of acres of farmland at Martin Farms — influence the decisions he makes as he tries to be the most efficient, cost-effective and environmentally conscious farmer he can be.

But a unique partnership with Kansas State University has helped equip Martin, and farmers like him across the country and globe, with precise information and best-informed practices, so he can implement decisions to make him the most successful farmer he can be.

Over the past 30 years, K-State researchers have partnered with local producers like Martin Farms to study, hone and implement precision agriculture techniques.

It’s research that has allowed Martin Farms to take each ‘next step’ to overcome any obstacles and become a next-generation farm, Martin said.

“There are times when you feel like you are stubbing your toe, so we say, or having a problem,” he said. “You just have to work through the problem to get to the next step, and that’s what we’ve done with these farms. K-State has been on the cutting edge forever, and that’s why we partner so well.”

These innovations — while helpful to Martin Farms across 2,000 acres of farmland in northcentral Kansas — are real-world use-cases that also inform agriculture research, implementation and product development around the globe, said Ajay Sharda, professor of biological and agricultural engineering and director of K-State’s Institute for Digital Agriculture and Advanced Analytics, or ID3A.

He has worked directly with Martin Farms since he arrived at K-State in 2014.

“This partnership has been just amazing, considering that we do not have our own farmland at this scale, and these projects — which are basically with real-world, state-of-the-art technologies — are happening on field scale in active collaboration with the growers and in active discussion with the global growers,” Sharda said.

On Martin’s farm, Sharda and a team of interdisciplinary faculty, graduate students and undergraduate students have studied precision agriculture practices and technology.

That has included advanced planters and aerial seeders that can sow seeds and nutrients at variable rates and cameras that can identify specific weeds to target in a field.

All of that work is backed by advanced sensors and data on conditions such as electrical conductivity, soil moisture and temperature and nutrient needs that give Martin and the researchers a more precise idea of field conditions, and how to use them to their advantage.

There’s simply no alternative to doing this kind of research on a working farm, Sharda said.

“When we do these research projects on a large field scale and present these results, not only do we as researchers learn things which are spatially variable, it’s something where farmers can say, ‘This is the kind of farm I farm,'” Sharda said.

Farming manufacturers, especially those in the realm of precision agriculture, can also use the data to better understand how effective their machines, control systems and sensors are in a real-world scenario.

“This is a very holistic systems level approach, where everybody who is a stakeholder is engaged, everybody who is a stakeholder is a partner in developing the knowledge, and everybody who is a stakeholder is a partner in furthering the knowledge we create,” Sharda said.