Since 2022, Sam Gleue has been the in-house engraver for Smith & Wesson. Daily, he works on designing and implementing artwork on all styles of S&W firearms out of Massachusetts; he also does custom work for existing customers’ guns that they ship in for customization.

Now 32, Gleue (pronounced Gloy) grew up in Wakefield and graduated from Chapman High School.

“I got recruited to Emporia for football, but it turns out it’s the only university in the country that offers a four-year engraving degree,” he said. “The odds of that happening were slim-to-none. My advisor told me I needed to take an engraving class, and it was pretty much over from there,” he said

At 6’9”, the backup left tackle said his football career came to a head when practice interfered with engraving classes during sophomore year.

“They went a little later and Coach said I couldn’t take them because it would cut into practice time; at that point I had a decision to make,” he said. “I just kind of put all the chips into engraving.”

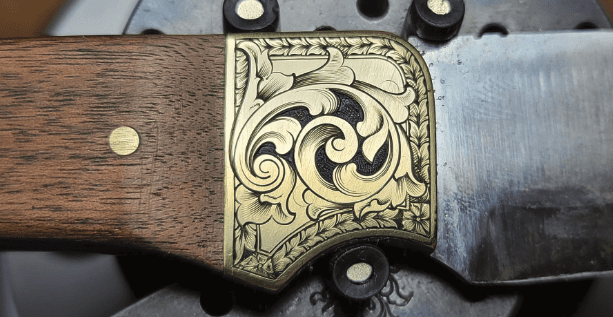

He works by looking through a microscope with the piece held in a ball vice. His left hand maneuvers the vice while his right hand holds the pneumatic graver. Similar to a tattoo machine, Gleue said, there’s a piston and spring that mimics the motion of hammering a chisel. The machine is powered by air and controlled by a foot pedal.

He adds tungsten carbide gravers, which Gleue angles by hand. His go-to angles are 90, 105, 120, and a flat. He said shaping them himself gives more control over the tool and the cuts they make.

“If there’s any variation in my sharpening fixture, then its at least consistent when shaping the graver from the beginning.”

Gleue credited his childhood on the family farm near Wakefield, owned by the Grandpa he’s named after, with providing interest in the art form, even if he didn’t realize it at the time.

“Growing up a lot at Grandpa’s house and being around all the shotguns that have engraving, Remington Flymaster, Wingmaster, scrollwork, pheasants, hunting dogs,” he said. “I’d been introduced to the idea but didn’t know it could be a job until I started taking these classes and researching it more.”

Looking at career paths, Gleue said he had two choices: firearms or jewelry, with the latter being more accessible. He interned locally at Hoover Jewelers, when the owner and namesake told him to attend a 12-week certification program in Tennessee.

“I figured I could get a job anywhere and continue to engrave but also get another skillset under my belt.”

Gleue went on to work for two different jewelers in the Kansas City area, before relocating to Texas.

“There came a point where I felt like I wanted to do more learning and continue to expand my horizons a little bit,” he said. This led him to a custom jewelry shop in Fort Collins, CO.

“A lot of it was fabrication and creating new things; I also got to help create the owner’s designs,” he said. “I think that was the most fun jewelry job I had.”

That’s when an opportunity came along that Gleue couldn’t pass up: Smith & Wesson was hiring an engraver.

“I immediately reached out, still sitting at my bench,” he said. “It’s not that I was trying to leave the store, but a full-time hand engraving position was one of my big goals, and the opportunity presented itself.”

Gleue was flown out for an interview where he met S&W legend, Dave Misiaszek, who would soon retire.

“Just being able to nerd out with someone, that was really fun,” he said. “It’s a pretty niche art style so being able to relate to somebody on that level with all the rhetoric and different terminology and them knowing exactly what you’re talking about is very exciting.”

Since 2022, he’s been the only in-house engraver with S&W, where Gleue does a variety of work, from hand-drawing designs, to digital vectors. That includes a combination of in-house designs, to custom orders on personally owned firearms.

With the latter, he said customers send in their gun, which is then inspected and serviced, polished, then sent to him for engraving. A company liaison coordinates the design and communicates with Gleue.

First, he offers a hand-drawn layout, and after approval, a digital version is submitted before the engraving begins. He spends anywhere from a few hours to up to two weeks on a firearm, depending on the order and size.

Price also varies from $20 per letter to full scrollwork on an X frame, 8-inch barrel, which runs $8,900. That includes 100% coverage on the engrave-able surface, he said. However, if a customer opted for a relief background – where the background is carved, leaving the design portion raised – the price doubles at nearly $16,000. Gleue said he has only engraved this style on smaller barreled firearms.

“I’ve found the more coverage, the more difficult the composition becomes – not because of the time or the amount – but you want to make sure the whole design looks like it’s supposed to be there; you don’t want it to look like patchwork.”

He also offers scenes, gold inlay, or custom portraits in addition to American scrollwork. It’s a style he chooses to continue due to its longstanding history with S&W.

Meanwhile, Gleue said revolvers are the most difficult to engrave due to their extreme curves.

“It’s a challenge because to maintain line consistency, you have to maintain your angle of attack,” he said. “Luckily, they’ve been engraving guns for 173 years so there are a lot of fixtures that make holding the piece easier.”

Off the clock, Gleue still fabricates jewelry and engraves metals, like knives, mementos, or belt buckles.

“Anything that can fit in the vice and is metal can be engraved,” he said. “Right now there’s a set of glassblowing tweezers that I need to finish.”

Nearly four years into his S&W career and over a decade in engraving itself, Gleue said he’s finally confident in what he can do.

“I can happily say mistakes don’t happen very often anymore,” he said. “Usually, if I do make a mistake, it’s due to the density of the steel, which causes my graver to break, which unfortunately can happen, and you have to burnish or buff it out. I look back at some of my early work and can see a lot of variations; I had the right idea but it wasn’t applied. You can see the progression year by year for sure.”