Part one, featuring a history of Clay Center Public Utility Commission was printed in last week’s paper. You can find it at KCLYradio.com

CCPUC is a self-funded entity that serves more than 5,000 customers. It employs 32 full-time employees and five part-time summer employees. A total of 13 of those workers, including maintenance, man the power plant 24-hours a day.

This allows water and power to be monitored round-the-clock. It also quickens the ability to fix an issue if power or water to go out, said Public Utilities Superintendent, Scott Glaves.

This is done by rotating shifts, he said. Meaning employees of the PUC will switch between day and night working hours.

“There are two guys on every shift, but it takes a while to get used to doing days, then nights, and switching,” he said. “That’s the hardest part of filling those jobs but once they get into the rotation we’ve had guys work 20 or even 40 years. It’s a rhythm to get into.”

Part of their responsibilities are watching computers that show real-time data on our area’s power grid and water supply. Alarms will sound if either needs attention, and it’s up to the on-shift team to jump into problem-solving mode.

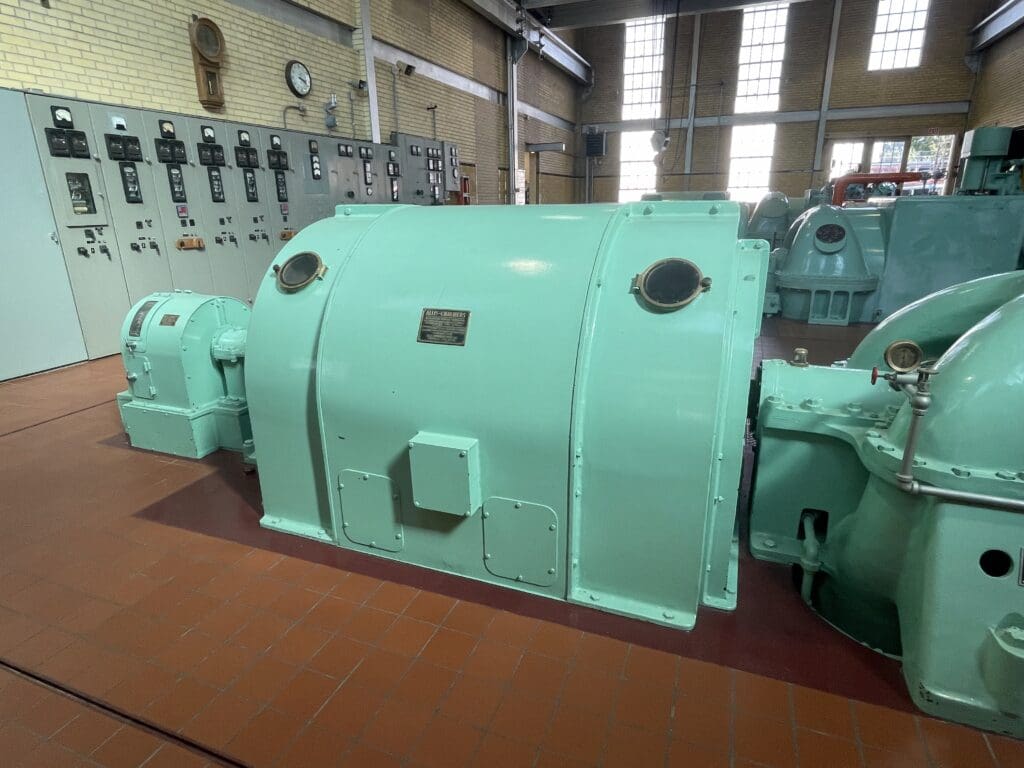

Another part of the job may be running generators, depending on the day or need for power, Glaves said. Generator engines are manually run, which takes years of experience to learn.

Prices and current need for power are two of the main factors that determine if PUC’s generators will run. Every day they have six units with the ability to create power locally, or to sell to the grid.

Glaves reviews multiple charts, which are updated in real-time, to predict both variables. Many factors come into play he said, including wind, temperature, fuel prices, and the need for power both locally and across the Southwest Power Pool, or SPP region. Some live charts are also available for public view. All of this, he said, depends if PUC will run its generators.

Essentially, the source with the cheapest bid will create the power. That includes anyone in the SPP, of which PUC is a member. SPP is made up of most of the Dakotas and Nebraska, all of Kansas and Oklahoma, and parts of Missouri, Arkansas, Iowa, New Mexico, Louisiana, and the Texas panhandle.

“Basically we can all import and export with each other, if it’s a hot day in Kansas and we’re short, we can import from another RTO [Regional Transmission Organization,” he said. “It gets confusing, we try and guess when Clay Center is going to need it but it’s a challenge. When there’s a high load and the wind quits blowing, you’re probably going to run.”

Glaves will know a day in advance if they will be generating, he said.

“We do get picked up in reliability run,” he said. “If the real time generation is short we can run for a four-hour minimum, or as long as it takes for the generation to catch up to the load.”

He added that Kansas is a wind-driven market.

“We’re constantly balancing like a yoyo, the load goes up and down,” he said.

In fall the load comes down after the head of summer – Clay Center’s peak season – before ramping back up in winter. He said some of the coldest winter days rival summer peaks. Meanwhile, there’s another lull in spring.

The PUC plant at full capacity can generate 23 megawatts per hour and the system peak is about 16 mw in July or August. Glaves said this summer peak is a day of 104-105 degrees when rural irrigations are running at the same time.

“We have some excess capacity, which is good. You want to have more generation capacity than you use.”

Currently, he said one generator is waiting on a part that was shipped from Germany, at which point it will be back up and running. The PUC has two additional generators in an exterior building, which can be used to start restart plant operations if power is lost.

In Clay Center, transmission lines come out of Chapman, though Glaves said an additional connection point to Clay Center would create more reliability. Just seven years ago a transmission line was severed by a tornado and PUC ran for 48 hours before the line could be fixed.

Ice storms are the main issue in Kansas, he said. While tornados or summer weather is quick and sporadic, ice can be widespread and stay on lines for days.

Like in 2007 when an ice storm took out key infrastructure.

“The phone rang for three days, everybody was strapped,” he said. “Contractors came in. That one was a doozie.”

However, due to FEMA funding and foresight by the previous PUC superintendent, Bill Callaway, infrastructure was rebuilt.

Glaves said about 90% of lines are robust and in good shape. He added that Callaway, who worked at the PUC for 43 years, was ahead of the curve, opting for 100% secure and fiber, which allows everything to be monitored safely at all hours.

“There are so many benefits to having your own power plant, when something does happen, like a natural disaster, we can run. We live in a world where you need power and if you just rely on the outside world, stuff happens. We maintain those engines for our community to keep the lights on. We’ve got a power plant so that nobody’s lights are going off.”

Another issue in the past has been when southern states saw unusually cool temperatures and natural gas couldn’t be ran through the pipelines, which is a main source of fuel used to make electricity.

“That happened a few years ago and it taught a lot of people a lot of lessons,” he said. “We can run on diesel if needed but it was very expensive. Energy prices just went absolutely bonkers and stayed that way for a three-day period.”

Regular maintenance to the engines includes lubing, preheating the oil that circulates warm 24/7, and more. Depending on the load time at the time, should a main line go out, Glaves said they can have the whole town up and running within 15-20 minutes.

Depending on the engine, it will need to run before it can take on a load. PUC also has their “black start engine” which is used to warm up or start larger models. That can be more difficult in the winter, he said, when the air is cold and has to be heated before it can circulated through a generator.

“Once the building Is warmed up there’s a lot more fine-tuning with the engines in the winter,” he said. Another high point is cleaning the power plant, which is nearly spotless, a rare point for an industrial location.

“In the utility business, it never stops,” he said. “The staff does a great job and we keep them really busy.”

Above: An Allis-Chalmers generator in the CC Power Plant. Left: original gauges on display, however, machines are now monitored digitally.