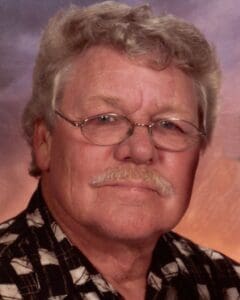

In 2011 the Regier family made significant career changes. Nick and Lundee were married a year prior; they met when Nick served as an ag teacher and taught Lundee’s younger brother. Before their first anniversary, she graduated college at K-State. While Nick had been doing woodwork on the side of teaching and was too busy to continue both, he said.

“It just kind of got to a point where you can’t give your all to both of them so you have to pick or choose,” he said. Saying they’d been discussing the idea of going into cabinet building full-time.

“It was kind of, we were young and dumb and we both jumped in,” she said. In the meantime, Lundee had begun clinical for becoming a speech pathologist, but soon decided it wasn’t the path for her.

The pair built a shop behind their house while Nick built and she stained cabinets and handled the business side of the company, including designing.

“We had some very good customers up front that took a shot with us,” he said. “A lot of people ask why did you do it and I say ‘I don’t have a clue.’ Looking back and knowing what it takes to make it in any business, we were incredibly naïve. It worked out well but to look back at that decision knowing what I know now, I don’t know that we would make it again.”

Now, Regier’s Custom Woodworking has three full-time employees in addition to the pair. Lundee focuses solely on business tasks and helping customers design their ideal outcomes. In fact, it’s closer to her dream career than she could have imagined. Previously wanting to go into interior design, she said helping layout cabinets is right up her alley.

On average, they handle 20-30 projects a year. It starts with a cold call where Lundee does the “hard work,” Nick says.

“Ultimately, the decision-making is probably the hardest part for the customer and she has to shoulder that,” he said. “When it gets to me it’s a matter of putting the nuts and bolts together.”

From there, Nick lays out the plans while he and his employees build the cabinets. He said all three work on the same project at a time, before hauling and installing once complete. His three employees have an array of work backgrounds and degrees, all having worked various jobs outside of carpentry, including a classical guitar major and a master’s in geology.

“They were pretty green when they came in, and maybe that’s not the right way to do it,” he said. “But we’ve hired for character and taught them the skills. Now each has their niche and what they’re most comfortable with.”

Lundee said it’s been a great fit with the team. “When it’s your name on the product, your heart needs to go into it and have attention for detail,” she said. “People want quality and we appreciate that. It’s been a really good fit for our business.”

Their first full-timer was hired in 2017 and two more in years since.

Over the past decade, the Regiers said they’ve seen styles change. Years ago most of their projects were painted, while now they are seeing mostly bare wood. Then from darker tones to lighter, more rustic, to now more modern. Overall, white oak, rustic hickory, and beach are the most popular choices.

Lundee said they also see more of their customers focus on what the space can do.

“Most people want function over fancy,” she said. “There are a lot of custom options and some do choose them, but it all costs money and we see most people putting their money into other things.”

In cabinets, soft closes are now standard – meaning even when slammed, doors and drawers close quietly. Then there are entire books of customizations or add-ons that can be picked by the client. From mixer lifts, to slides or appliance garages. While trash pull-outs and lazy Susans are essentially standard in every kitchen job.

However, with custom-built solutions, Regiers focus on high-quality elements that last.

“This is what brings us the greatest enjoyment, is building a project that benefits their family,” said Nick. “We’ve done a lot of remodels that have totally change how a family can function and I feel like people want their space to make their lives easier.”

Though Nick has always enjoyed woodworking, he took on his first kitchen project for his parents’ house as a freshman in college.

“That was the first big thing I did,” he said. “I’ve always liked building stuff. My Mom was an art teacher and my Dad a farmer so it was a good mix between building and being artistic.”

His projects began growing by word-of-mouth, leading to cabinets for not only kitchens, but bathrooms, laundry rooms, mudrooms, basements, and other functional home spaces.

Finishing touches include hardware and countertops, for which they work with area partners. However, one area they didn’t expect to see such a change with their business was politics. Because they often obtain lumber from overseas, the political climate affects not only prices, but availability, they said. During COVID their biggest hangup was obtaining drawer slides, which are exclusively Swiss or German.

“We scavenged and found as much as we could from different places,” Nick said. “We were online; the price didn’t matter at that point we were just trying to find them.”

Different weather events have also made it hard to obtain lumber, hinges, and more.

“The World political and economic situation does trickle down here,” Lundee said. Adding that beechwood is often from Germany, several styles come from Africa, and hardwoods are from Appalachia. “It’s interesting how domestic and global affects us even in rural areas.”

Today, the venture has supported the family for 14 years with steady projects in its sights. The schedule always ebbs and flows, Nick said, leaving them to pick up smaller projects if and when they are able.

“Everything we do is custom so it’s unique,” Lundee said. “Everything else I learned through screwups and fixing my mistakes. Thankfully we had people willing to take a chance with us.”