Kansas State University engineers are developing advanced technology to monitor rail stress in continuously welded steel railroad tracks without physical contact.

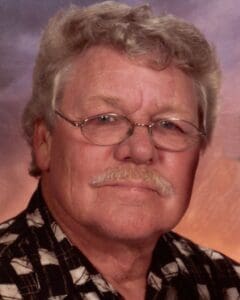

Professor B. Terry Beck from the Carl R. Ice College of Engineering secured over $300,000 in grant funding from the U.S. Department of Transportation to lead the project. He is collaborating with civil engineering professor Robert J. Peterman, engineering director John Bloomfield from K-State’s Technology Development Institute, and BNSF Railway. Mechanical engineering graduate student Veeshal Modi is also involved.

Detecting rail stress is crucial for preventing derailments caused by extreme temperatures. Hot weather can cause track buckling due to excessive compressive stress, while cold temperatures can lead to rail fractures from tensile stress, both of which worsen under train loads.

Currently, no reliable non-contact method exists for monitoring rail stress. This project will use advanced strain-measurement technology to track rail displacement and temperature, aiming to improve railway safety. The team will test the method in a lab and conduct field trials with BNSF Railway, potentially offering a breakthrough solution for the railroad industry.