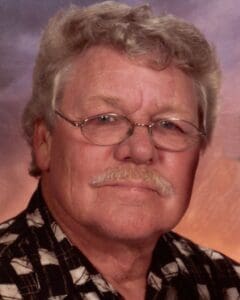

In the early 2000s, Nate Boyer began work on his first car. At just 13 years old he bought a ’59 Volkswagen Beetle, spending his $1,000 savings – earned from mowing laws – on what would be the first of many restorations.

After years of work in his parents’ Clay Center driveway and help from others – his Dad, family friends, and a local body shop to paint – it became his first car. The pearly blue bug became a staple in both the CCCHS parking lot and around town.

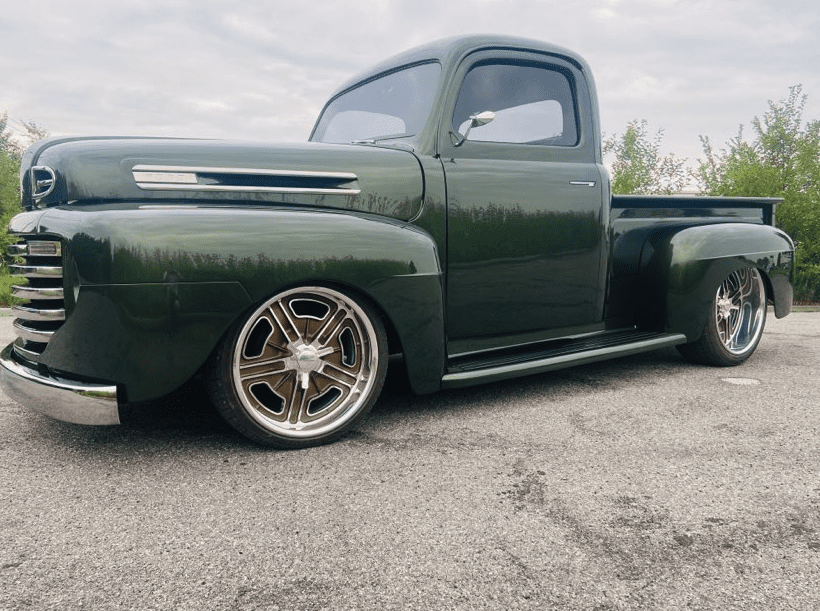

That was the beginning of what would become a career path slated in remodels. But not just body and paint work, but complete restorations. In 2007, at just 20, Boyer opened Kultured Customs Restorations in Gardner, Kansas, where he began refurbishing old cars. From rust buckets to shiny, drivable vehicles, he jumped into the world of professional restorations.

“Most aren’t trying to make magazines or go to competitions, they just want what we call a ‘daily driver,’ a nice, clean car that they can drive around,” he said. Adding that these projects usually range between $80,000-$120,000 a pop.

Meanwhile, show cars cost between $200,000-$300,000, but was quick to add that it’s a budget that won’t win any national competitions.

“Our show projects, they’ve fallen short most of the time, that market has changed so much with technology.” For a show car to be competitive, Boyer said it’s about a half-million investment, a market that just isn’t available in Gardner. A fact he’s not upset about.

“We don’t have that client base and don’t really want them,” he said. “It really has turned into who has the most money and that’s just not why I got into restoring cars.”

Kultured Custom books cars that are from the 1970s and older.

“It just feels weird calling something from the 80s an antique.”

The average time spent on each car at Kultured Customs is 18 months, while the wait to get in the door is far longer, between two and three years.

“At any given time we have at least a two-year backlog,” he said. But quality work takes time, and older cars require some TLC, especially when refinishing the finer details.

Right now, there are five cars in the shop, he said. The oldest being a ’31 Ford Coupe and the newest is a ’72 Chevy pickup.

In its 17 years, the shop has hosted two TV shows, Chop Cut Rebuild on Speed for 12 episodes, and Gear Dogs (2017), which aired on six episodes on Discovery. The latter featured hobby mechanics who used Boyer’s space to restore their projects, leaving Boyer with a cut of the selling price.

“It got to be too much to handle; it grew too big,” he said of the Doghouse approach. “For me it was just a passion project, I wasn’t trying to change the scope of anything, just make it fun. We’re just car guys working on cars.”

Still in the same shop where he began, Boyer was quick to point out that he doesn’t like change – a theme in many areas of his life. He grew up in the same house since he was 1 – his parents still live there. And he’s still fixing up what was once new.

“I got into it because I thought old cars are cool. And I thought if I was building hotrods I’d get the chicks,” he said. Adding that the theory did, in fact, get him the chick – he’s been with his wife, Ami, a heavy equipment operator, for 10 years. The pair also have three kids, Cash, 14, Sailor, 7, and Georgia, 6,

Ami drives a ’59 Fairlane that she drives as often as Boyer can keep it running, he said. And though he’s rebuilt hundreds of cars, Boyer himself drives an older Civic, and also has a 2500 truck. In fact, he has never had a hotrod of his own.

“I fix cars all day, the last thing I want to do is come home and fix my own stuff,” he said. “I like driving beaters, something I don’t feel bad about messing up.”

But his work with cars doesn’t stop there, he’s also a teacher at the Gardner High School, teaching the collision and refinishing class. Last year he filled in for the automotive class and was asked to stick around for good. For Boyer, it’s the best of both worlds.

On weekdays he teaches three classes, spanning about four-and-a-half hours, then heads to the shop to work on cars. In the meantime, his employees work behind the scenes, keeping the progress moving forward.

“It’s a good group of guys,” he said. Currently he has four employees but has had up to nine.

“The money seems to be about the same, but with less I enjoy it more. There are fewer headaches,” he said. “Either I wanted to build hotrods or I wanted to go be a shop teacher,” he said. “This was the opportunity to fulfill that. I couldn’t be happier.”